热门产品

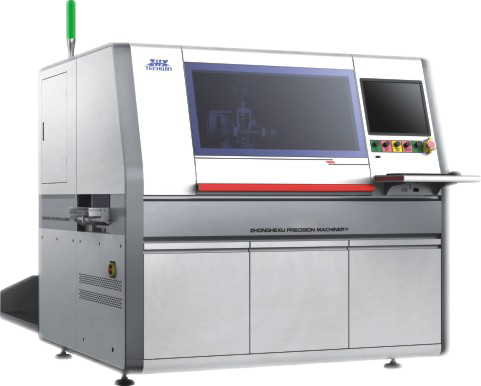

高精度视觉坐标定位系统,通过插入位置的所有孔( 2孔或3孔)的位置识别,计算出最佳插件位置进行算法补正,辅助以精密机械PIN针定位系统,实现稳定插件植入。从机器底座、头部基座、到料站部品,大范围采用一体式铸造成型工艺,特殊抗应力工艺处理,确保整体可靠性,配合高精密加工组件,实现设备更持久稳定的运行。

热门产品

凭借选装全新的自由旋转平台,您可以轻松实现360°任意角度插件制程需求,极大地降低制程瓶颈和人工干预。这一创新型结构创意,使得HA/MA系列一举成为业内最具适应性的卧式插件机。全新开发的智能模块化供料器,占地面积更集约,但依然实现了28000点/小时的超高速产能搭载。从容实现最高等 级面积性条件下的高效率生产。您还可以通过拓展最多达80站,以应对未来出现的制程需求。

热门产品

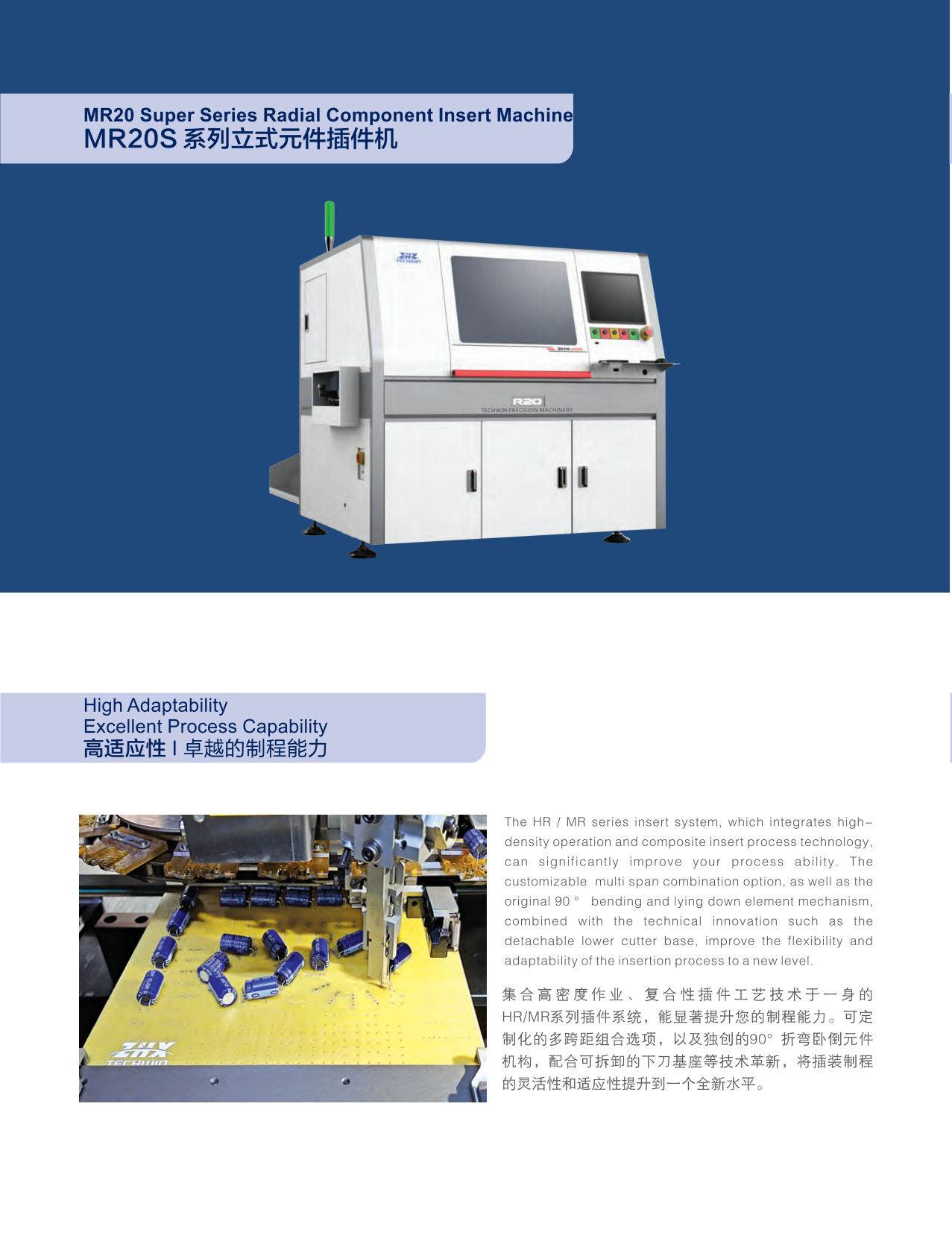

HR系列以0.22秒/件(最佳状态可达)的实际插装速度 (UPH),MR系列以0.26秒/件(最佳状态可达)的实际 插装速度(UPH),轻易将生产线前后制程效率的平衡问 题提升到一个全新水平。其最佳300PPM (可达)插入不 良率表现,更是将设备稼动率、系统生产力提升到前所未 有的高度。

热门产品

MR20

热门产品

面对脆弱的元器件引脚,您需要高精度的传输组件来保证传输过程中不会变形。我们的高精密传输系统可以在最高 0.15秒/件的效率下,依然保证元器件引脚不会发生形变, 从而带来最高的连续制程可靠性。

热门产品

全新的智能轨道传输系统,不再是简单的机械停板装置, 而是由程序根据生产状态,及时传输PCB,减少等待时 间。您还可以通过选装离线编程系统,降低换线时间,提高制程运行效率。

热门产品

高精度智能化搭载两组高精度识别相机的Y30平台,能快速识别元器件不良;每个插装头采用独立信号控制,通过元器件重量及高度的精准 测量反馈,和元件取料方式差异,合理分配Z轴加速度,从容应对 XY轴高速运动下产生的力矩,确保每次插入合格率。插装头杆的纳 米金刚石涂层技术,可在极低的维护成本下保持高效运转。

热门产品

紧凑的模组化设计,可以执行灵活的单机插装任务,您可以并入现 有产线或配置新的产线来配合使用,达到产能平衡,实现模组化设计的真正价值。设计方面的创新和高新材料的使用降低了运动悬臂和插装头部重量,轻盈带来敏捷性。X轴悬臂采用带精密光栅尺编码器的线性马达同步驱动,为多达3G重力加速度运动下的机械精度 提供绝佳保障。

热门产品

XY伺服电机驱动,实现高度自动化,10分钟内可完成正产准备,0°-360°可自由编程的插入角度(增量为10,旋转角度对插入速率没有影响),插入速率高达3.3/秒(每次冲程1个触点)。下部下刀在插入过程中同步箝紧,杜绝浮高,支持标准封装供料和散料振动盘供给方案。

热门产品

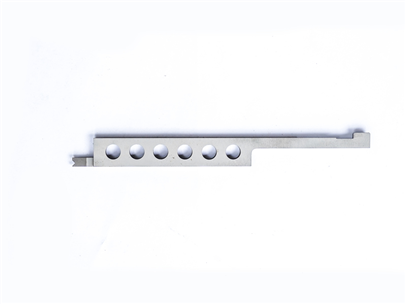

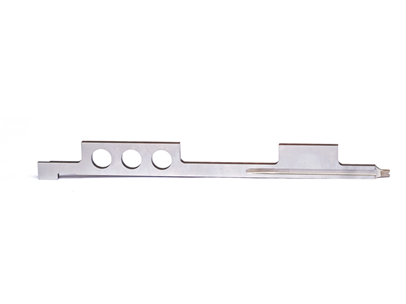

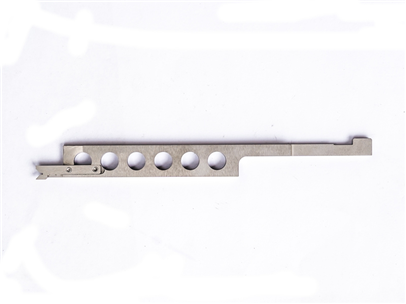

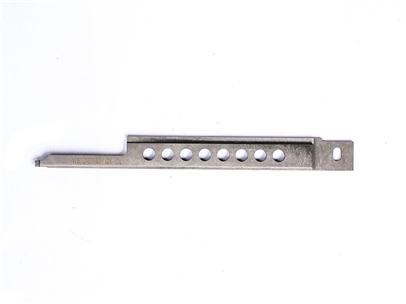

自动插件:通过精密的机械结构,能够准确快速地将弹片插入到产品的指定位置高速生产:能够在短时间内完成大量的插件任务高兼容性:能够适应不同规格和形状的金属弹片,通过简单的调整和更换配件,适应不同的产品需求,提供定制化的插件解决方案。

热门产品

波峰焊接方案Micropeak +氮气/非氮气全新氮气波峰焊接系统► 精确氧浓度数据监测分析► 高效 高品质焊接► 低故障 低维护率► 更低的制程损耗

热门产品

回流焊系统作为SMT制程中较为耗能的环节,如何降低其对整个制程供电系统的冲击,是需要慎重考虑的问题。Vision系列回流焊采用线性加热方案,全闭环算法控制,大幅降低启动功 率,减少电网冲击,保证系统供电稳定性的同时,也大大降低的系统能耗。

热门产品

焊料温度的稳定性对焊接品质尤为重要。Micropeak Nitro系列波峰焊接系统独特的分层加热温控技术,配合特殊铜介质传导的加热器,可快速而精准地实时控制炉温,降低电网负荷冲击和能源消耗。独有的陶瓷防护层炉胆,能有效抵抗金属高温腐蚀,防止制程污染。

热门产品

节能、高制程灵活性、高可靠性-全新Vision系列回流焊系统, 有效解决了回流焊接设备困扰SMT制程的环保、 能耗、系统 灵活性等一系列难题。中禾旭凭借多年热工领域技术沉淀,打造的全新Vision系列回流焊接系统,这一解决方案集成了超低能 耗、超高选配组合灵活性、高可靠性、易维护等优点,使您的生产制程更加灵活、稳定、高效,避免更多的能源消耗,显著降 低生产成本。

热门产品

面对越来越多的AB双面制程工艺,我们巧妙地在同一平 台搭载了内置翻板装置,从而轻易解决一套系统兼容两个制程的需求。提高运行效率的同时,也降低了设备资金投入,实现最高单位面积生产性。

热门产品

简约但不简单。我们的桌面式激光打标机被证明能在最严苛的生产环境中,在最具挑战性的精密部件或基材上打标,从电子元件到芯片,从树脂类聚合物产品到金属部品,针对您的所有制程标记打标和追溯需求,我们都有专业的赋码解决方案。

热门产品

其对常见的焊锡不良如空洞、连锡、虚焊、锡珠、热敏元件受损等制程难题,以及不规则部品、非接触式焊接需求,具有令人信服的突破性贡献,可以轻松匹配您的锡球、锡膏和锡线、精密金属结构件等焊接制程需求。

热门产品

视觉系统自动检测不良并确定位置。对少焊,漏焊,多焊,连焊等多种不良进行处理。定位视觉和监控视觉相互辅助,操作更简便。独特的数据交换使每一次处理更加精准。

热门产品

独立排放结构、提高清洁度。自动加助焊剂、减少人工参与。智能选择性喷雾。

热门产品

全自动化操作:实现了上下板过程的完全自动化,无需人工介入,大幅提升工作效率,降低劳动强度。高精度定位:能够精准地将板子放置在指定位置,保证后续生产流程的准确性和一致性。

热门产品

高效无缝衔接:能够实现不同生产环节之间的高效、无缝对接,确保生产流程的连续性和稳定性。自动化传输:无需人工推动或搬运产品,自动完成产品在不同工位之间的传输,提高生产效率。精准定位:可以精确地将产品定位到指定位置,减少位置偏差,保证后续加工或组装的准确性。

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960

热门产品

机器维修:13823330960